High Purity Water Systems: Practical Uses, Benefits, and Key Considerations

Why High Purity Water Matters Across Industries

Water devoid of contaminants isn’t just a technical preference—it’s a fundamental requirement for various mission-critical processes in industries where product failure, malfunction, or health risks are not an option. For example, in pharmaceutical production, unwanted ions or particulates can hinder chemical reactions or leave toxic residues, potentially jeopardizing patient safety. In the semiconductor industry, even the tiniest impurity can create defects on silicon wafers, leading to significant losses. Meanwhile, in research laboratories, purity guarantees the validity of experiments by preventing false readings and cross-contamination, which could otherwise undermine years of work or render scientific findings unreliable.

The demand for high purity water stretches across food production (where taste, texture, and shelf life can all be compromised by impurities); clinical diagnostics (where accuracy determines treatment choices); and advanced manufacturing processes like solar panel fabrication, where contamination can lead to catastrophic equipment failures or product recalls. As global supply chains become more complex, the importance of upholding stringent water quality standards is magnified.

Within the Maryland region, the bar is set exceptionally high—particularly in sectors like technology development and biomedicine, where water purity directly impacts compliance with federal and international regulations. Companies take no chances, often investing in advanced high-purity water treatment systems in Maryland that incorporate robust monitoring and fail-safes to ensure no deviations occur. These investments not only help organizations maintain quality but also support cutting-edge research, medical breakthroughs, and product innovation.

The Science of Water Purification

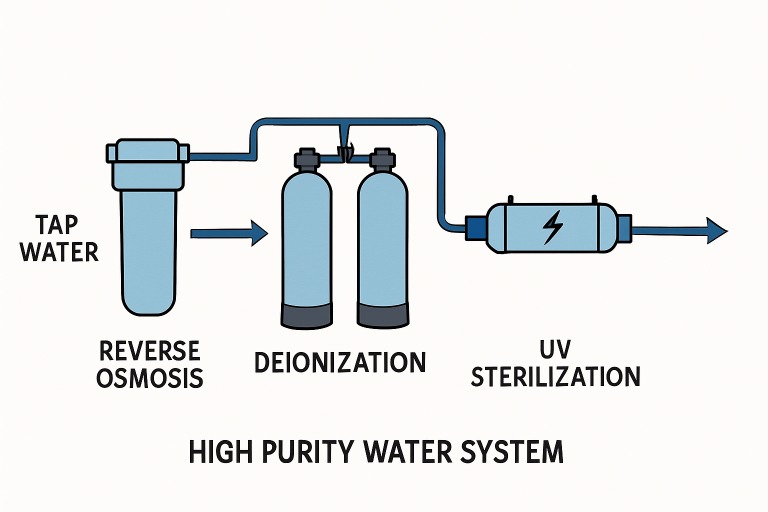

Producing high-purity water is a complex intersection of engineering design and modern chemical science. The journey begins with technologies such as reverse osmosis, which forces water through selectively permeable membranes to exclude dissolved minerals, salts, and contaminants. This is often followed by deionization, where ion-exchange resins remove remaining charged particles, and ultraviolet sterilization, which eliminates bacteria, viruses, and organic compounds. Together, these steps strip away nearly all impurities—creating water that is as close to chemically pure as possible.

According to the Centers for Disease Control and Prevention (CDC), a multi-barrier treatment process is best practice: each layer reduces the risk of harmful contaminants slipping through. Facilities don’t use a one-size-fits-all approach; system designs are customized based on the origin of the source water, the contaminants present, and application-specific purity requirements. Careful pre-treatment is often needed to prevent premature fouling or degradation of critical system components, while final filtration steps are tailored to the end-use scenario.

Emerging research is now examining ways to make these purification technologies more energy-efficient and less wasteful, balancing operational needs with sustainability goals. As new contaminants are identified and regulatory limits tighten, the science of purification continues to advance, ensuring that even the strictest purity standards can be reliably met.

Common Applications for High Purity Water

The reach of ultrapure water applications is extensive, encompassing numerous industries and specialized processes. In hospital clean rooms, sterile rinsing with pure water prevents infections and ensures the efficacy of medical instruments. Analytical laboratories depend on water free from trace metals, organic residues, or bacteria; any intrusion can distort data, causing financial losses or delaying time-sensitive research. High-purity water is also essential for calibrating lab instruments, dissolving reagents, and preparing culture media for cell biology experiments.

In the demanding environment of power generation, ultrapure water is used to cool equipment and generate steam, where the presence of dissolved solids could lead to the buildup of scale, corrosion, or mechanical failures. Maintaining purity protects vital assets—such as turbines and boilers—against damage, reduces the need for costly repairs, and extends the usable lifespan of equipment. Similarly, food and beverage manufacturers rely on high-purity water during ingredient mixing, cleaning, and bottling to ensure consistent taste, safety, and shelf life.

Strict regulatory requirements govern each application; pharmaceutical companies must adhere to pharmacopeial standards, while electronics manufacturers often follow ASTM or ISO purity grades unique to their sector. Any variation in water purity threatens not only the quality of the final product but also the credibility of entire organizations.

Monitoring Water Quality: Metrics and Standards

Maintaining high purity is only possible with precise, real-time monitoring. Key metrics include conductivity (which increases with the presence of dissolved ions), resistivity (which inversely reflects purity), and total organic carbon (TOC), whose elevated levels indicate insufficient removal of carbon-based contaminants. These measurements provide rapid feedback, allowing operators to quickly make water treatment adjustments as needed.

Respected organizations such as ASTM International and ISO have established detailed standards to classify various grades of high-purity water across industries. These standards ensure global consistency and compatibility, providing companies with a common language for quality and compliance. Additional parameters—such as microbial counts and the presence of endotoxins—may also be monitored, especially in clinical, biotechnological, or food-related settings.

As manufacturing processes grow more complex and cross-border trade increases, robust water quality monitoring becomes vital to guarantee the safety and reliability of exported goods. Stricter oversight also drives innovation in analytics, including the use of automated sampling and data-backed quality assurance programs.

Challenges in Producing and Maintaining Purity

The pathway to consistently high-purity water is riddled with hurdles. Raw source water may vary seasonally in composition or carry unexpected contaminants, creating challenges for system operators. Aging or corroded plumbing infrastructure can introduce trace metals or organics, requiring careful maintenance and periodic upgrades. Microbial contamination, which thrives in stagnant water or poorly maintained systems, poses perpetual risks, particularly for biopharmaceutical or healthcare environments.

Laboratories may confront the problem of leaching from storage tanks or sample containers, which can introduce unanticipated impurities after purification. In electronics and semiconductor manufacturing, the bar for acceptable particle levels keeps rising as device components shrink, intensifying the challenge to meet ever-stricter limits on water quality consistently. System failures or lapses in regular maintenance routines can have catastrophic financial and operational consequences, highlighting the need for ongoing vigilance.

The solution involves a multi-pronged approach: integrating real-time quality monitoring, establishing rigorous maintenance protocols, responding promptly to system alerts, and ensuring staff are highly trained on both routine issues and emergency response procedures. These measures, combined, make it possible to produce water that reliably meets even the toughest demands.

Recent Innovations Shaping the Field

Water purification technologies have undergone remarkable progress in recent years. Smart sensors and the Industrial Internet of Things (IIoT) are revolutionizing system monitoring by enabling automated, real-time tracking of water quality parameters. These advanced analytics can predict potential quality breaches and alert operators before minor issues escalate, vastly reducing downtime and maintenance costs.

Next-generation desalination and filtration systems now utilize materials that are not only more effective but also recyclable, thereby reducing their overall environmental impact. There is also a growing emphasis on energy-efficient form factors and system architectures—allowing facilities to lower their carbon footprint while maintaining uncompromising quality.

In practical terms, these innovations enable organizations to become both more cost-competitive and more sustainable, while enhancing the reliability and resilience of their water systems.

Best Practices for Facility Managers

- Perform regular calibration of all monitoring devices to guarantee the accuracy of purity measurements and avoid false assurance.

- Implement and maintain a structured preventative maintenance schedule, ensuring system longevity and rapidly addressing emerging issues before they affect operations.

- Invest in thorough training programs for staff, enabling effective troubleshooting and empowering personnel to respond confidently in the event of system deviations or emergencies.

- Keep detailed, easily accessible logs of all purity measurements, maintenance activities, and system performance reviews to facilitate audits and drive continuous improvement.

- Stay updated on changes in industry-specific regulations and advances in water treatment technology, ensuring your facility remains both compliant and at the forefront of best practice.

The Ongoing Future of High-Purity Water Systems

As the stakes for product quality, patient safety, and operational efficiency continue to rise, the importance of water purification will only intensify. Facilities that embrace continuous improvement and invest in durable, innovative water treatment systems will be best positioned to lead in their respective fields. Likewise, organizations that prioritize ongoing staff education, adapt to new regulatory guidance, and implement sustainable water use policies will help shape a future where both human health and industrial advancement are supported.

By fostering a culture of excellence around water purity—from strict process control to rapid technology adoption—leaders in today’s most advanced sectors will not only meet compliance goals but also drive global progress and set the standard for generations to come.