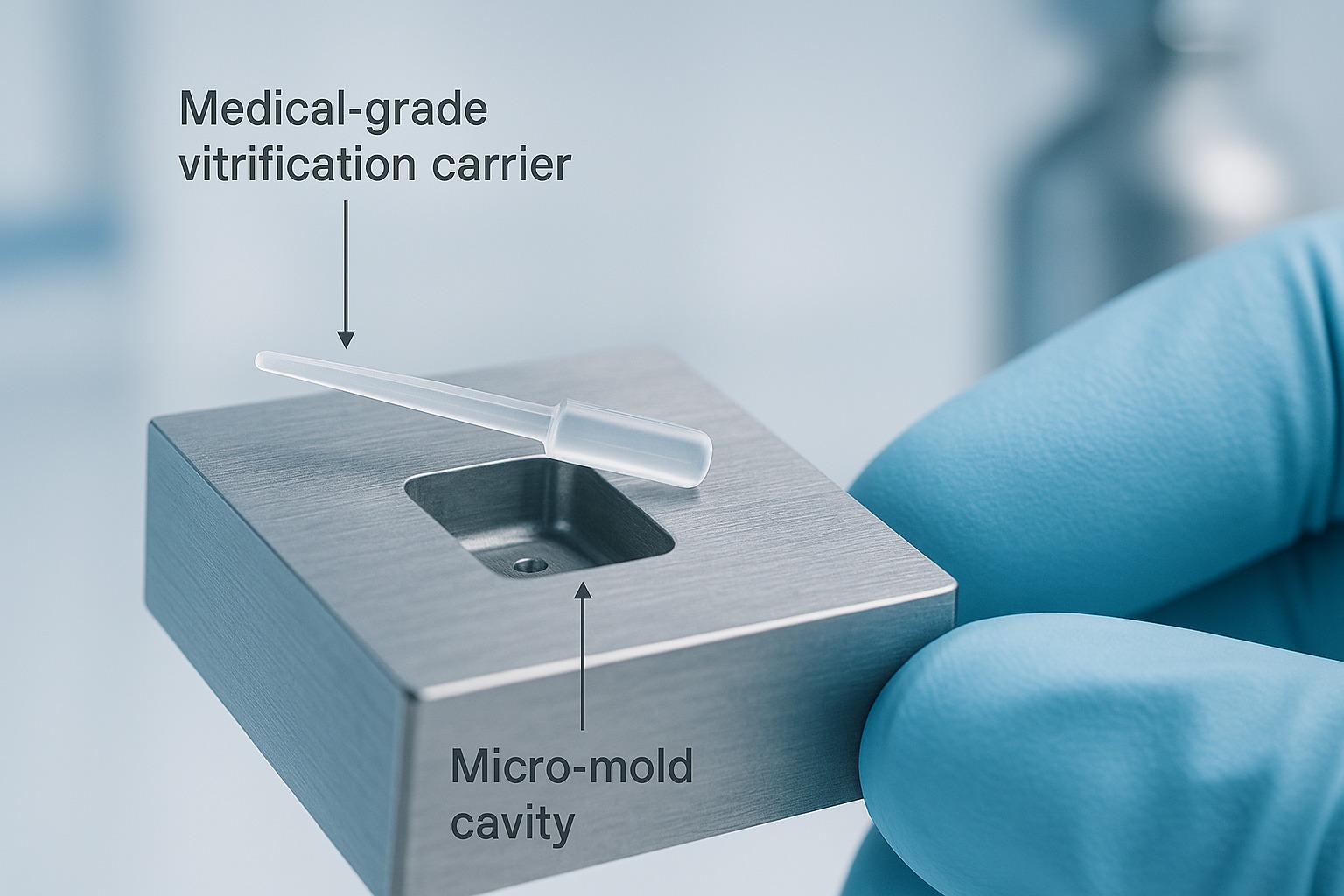

Why Micro Molding is Essential for Medical-Grade Vitrification Carrier Production

In the field of assisted reproductive technology and cryogenic preservation, precision and reliability are non-negotiable. Every component used in the process—from storage to handling—must meet strict standards of biocompatibility, dimensional accuracy, and consistency. Among these components, the vitrification carrier plays a vital role. Though small and often overlooked, its importance cannot be overstated. Producing such a highly specialized part requires advanced techniques, and that’s where micro molding has become indispensable.

Understanding the Vitrification Carrier

A vitrification carrier is a small device used to hold and protect embryos or oocytes during the vitrification process—a rapid-freezing method that avoids ice crystal formation. This method preserves delicate biological structures by transforming cellular water into a glass-like state. The carrier must maintain structural integrity at cryogenic temperatures and be chemically inert so as not to interfere with the viability of the preserved sample.

Because of the biological sensitivity and the life-changing implications of its use, every detail of the vitrification carrier must be flawlessly executed. A tiny inconsistency in wall thickness or surface finish could compromise its performance, which is why conventional manufacturing techniques fall short.

The Need for Micro Molding

Traditional manufacturing methods, such as CNC machining or manual assembly, are not well-suited to the production of micro-scale medical parts. These methods often result in variability, inefficiencies, and high production costs—especially when scaling is required. Micro molding, by contrast, offers the ability to produce high volumes of extremely small, intricate parts with tight tolerances.

Micro molding is a specialized branch of injection molding designed for components typically weighing less than a gram and featuring micro-scale features. For medical applications, especially those involving patient-critical components like vitrification carriers, micro molding provides unmatched repeatability, material efficiency, and cleanliness.

Benefits Specific to Vitrification Carriers

- High Precision: Vitrification carriers demand tight dimensional control—often within a few microns. Micro molding excels at delivering this level of accuracy, ensuring uniformity across every part.

- Material Compatibility: Medical-grade materials such as polycarbonate, COC (cyclic olefin copolymer), and medical-grade polypropylene can be used in micro molding. These materials offer clarity, thermal stability, and biocompatibility—essential features for a successful vitrification process.

- Surface Finish Control: Smooth, defect-free surfaces are critical when handling biological material. Micro molding tools can be polished or textured to achieve optimal surface conditions, reducing the risk of contamination or cell damage.

- Scalability: As demand for fertility treatments rises globally, clinics need a reliable supply of vitrification carriers. Micro molding allows for high-volume production without sacrificing quality, making it a cost-effective solution for manufacturers.

- Regulatory Compliance: The medical industry is heavily regulated. Micro molding facilities that produce vitrification carriers typically operate under ISO 13485 certification, ensuring compliance with international medical device standards.

Micro Molding Challenges and Solutions

Producing at a micro scale is not without challenges. The tooling involved is highly specialized and requires expert design and engineering. Material handling must be extremely precise, and the molding process demands tight control over factors such as temperature, injection speed, and cooling time.

To overcome these hurdles, manufacturers use state-of-the-art equipment, precision tooling, and rigorous quality assurance protocols. Advances in simulation software also allow engineers to model mold flow and optimize designs before production begins, reducing trial-and-error and improving speed to market.

Supporting the Future of Reproductive Health

As reproductive technologies evolve, so do the requirements for the devices that support them. Tomorrow’s vitrification carriers may include integrated labels, tamper-evident features, or improved ergonomic designs for lab technicians—all of which can be realized through micro molding.

Furthermore, the same techniques used for producing vitrification carriers are being applied to other medical innovations, including microfluidic devices, drug delivery systems, and implantable components. The demand for micro molding will continue to rise as medical devices shrink in size while growing in complexity.

Final Thoughts

The intersection of precision engineering and reproductive science is producing remarkable outcomes—and the vitrification carrier is a perfect example. Its production requires more than just technical ability; it demands a deep understanding of materials, biology, and process control. In this context, vitrification carrier medical micro molding is not simply a manufacturing method—it is the enabling technology that ensures quality, consistency, and trust in a device designed to preserve the beginnings of life.

As fertility science advances, the tools used must also evolve—and micro molding is leading that evolution.